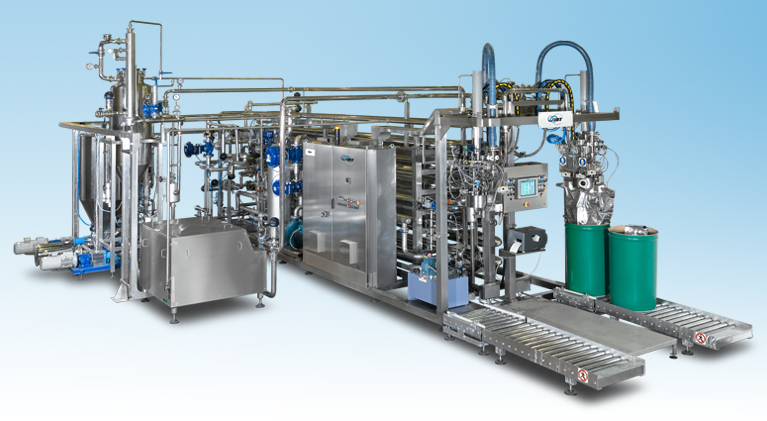

Our READYGo ASEPTIC MONOBLOCK is designed to supply the food processing industry with a small/medium-sized unit for aseptic processing and filling with the same high quality and aseptic reliability as large scale units.It features compact overall dimensions, quick and easy installation, high flexibility and simplicity of use. All the components are installed onto a single stainless steel mainframe and they are supplied with all the relevant piping and electrical connections.Before leaving factory, the unit undergoes a complete testing in order to have it all ready and set for installation at customer’s site in minimal time.

Features & Benefits

- Several feed tank options available

- No chemicals or sterile gases are used

- Capacity ranging from 500 to 6000 kg/h

- Greater versatility by meeting various packing standards

- The aseptic filling chamber can be open without losing asepticity

- High production speed achieved by a fully PLC-controlled self-diagnostic operational mode

- Simple installation, only connection that has to be made is with utilities (power, water, air and steam)

Details

- READYGo ASEPTIC MONOBLOCKS can process the following products:

- fruit purees with or without pieces

- concentrated fruit purees

- tomato-based non-concentrated products

- tomato products concentrated or semi-concentrated

- tomato and fruit dices

- vegetable purees

- clear or cloudy juices

- natural or concentrated

- other formulated products